Pro's and Con's of Conduit Types

Cable Options for Every Application

Conduit in a raised floor plenum environment?

NEC article 645.5 modifies article 300, permitting branch circuit conductors to be installed under a raised floor using Liquid Tight, Flexible Metal Conduit or MC Cable if the computer room meets the qualification as an Information Technology Equipment (ITE) room.

For more on NEC article 645.5, click here.

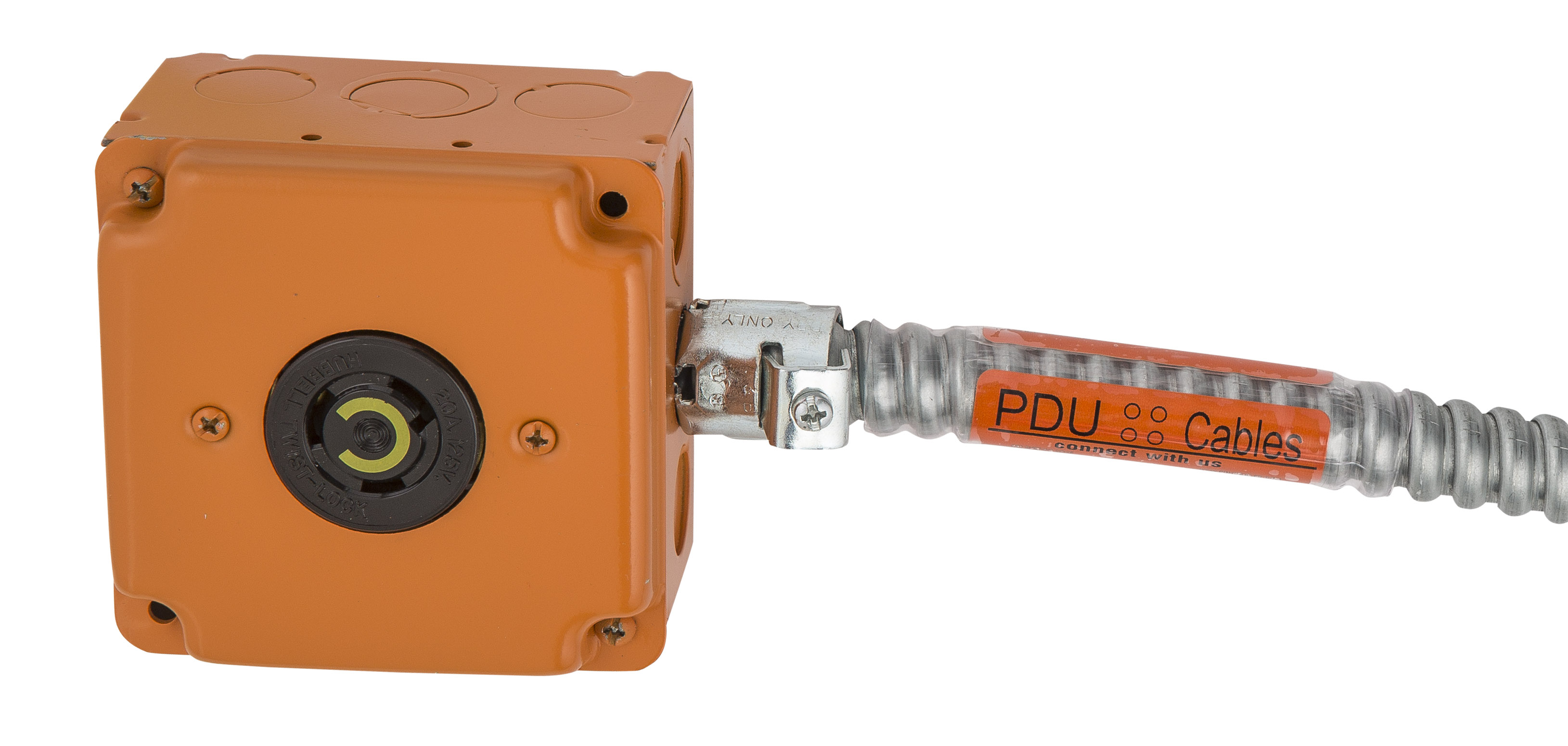

Liquid-Tight Flexible Metal Conduit (LFMC)

Pro’s

- Ideal for organizing dual power feeds

- Moisture resistant

- Label friendly

- Cost effective

Con’s

- Larger outer diameter

- Heavier weight

- Less flexible

Flexible Metal Conduit (RWS & RWA)

Pro’s

- Smaller outer diameter

- Lighter weight

- Cost effective compared to MC (less waste)

Con’s

- Lacking conduit color options

- Limits labeling options

- Dirty jacket residue

Metal Clad Cables (MC) Cables

Pro’s

- Smaller outer diameter

- Lighter weight

Con’s

- Risks in manufacturing process

- Limited standard conductor color options

- Lacking conduit color options

- Limits labeling options

- Dirty jacket residue

SO Cord

The types of SO Cord

- S = Service cord

- J = Junior service cord

- O = Oil-resistant outside jacket

- OO = Oil-resistant both inside insulation and outside jacket

- W = Compliance, Safety, Accountability (CSA) designation for weather and water resistance

- E = Elastomer

Pro’s

- Pliable

- Smaller outer diameter

- Moisture resistant

Con’s

- Expensive

- Jacket off gassing (odor)

- Jacket sticky attracts dust

- Termination issues

- Limited configuration options

- Lead times

- Lacking conduit color options

Tray Cable - STOOW

Pro’s

- UV, moisture and oil resistant

- Flexible, offers a tight bend radius, suited for overhead basket trays

- Label friendly

- Lighter weight than either LFMC or FMC

- Overhead friendly

Con’s

- Can only be UL listed with inline devices

- More expensive than traditional conduit options

- Lacks conduit color options