Overview

Receptacle Faceplate

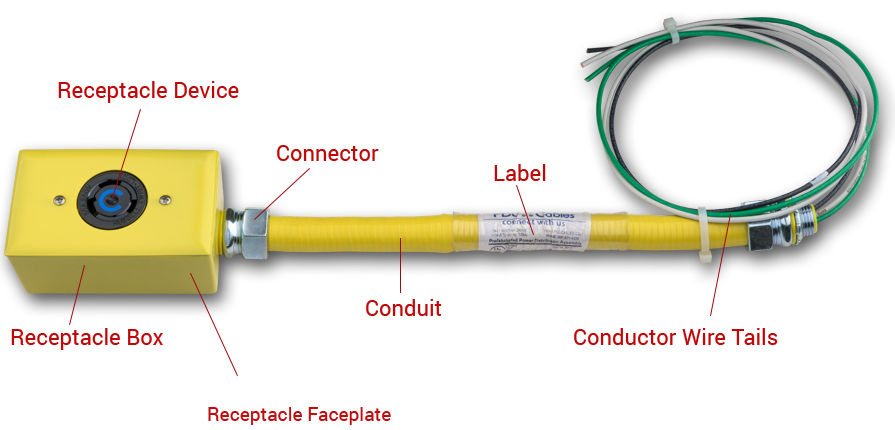

In addition to the basic receptacle faceplates, PDU Cables is able to offer NEMA style faceplates in the same eleven colors as the receptacle boxes and liquid tight flexible metal conduit. Faceplate labels are also available to display PDU/Panel number and/or circuit number.Receptacle Box

The receptacle box houses and protects the electrical device and its wiring.NEMA style boxes are offered in either weatherproof (cast) or 1900 options.

NEMA style boxes are offered in eleven colors in addition to the unpainted version.

IEC309 (Pin & Sleeve) receptacles are also available in a back-box version for mounting to underfloor supports and structure.

The number and size of conductors may dictate a deeper box.

Unsure what type of box you want, ask anyone of our sales associates, and they’ll help you decide what is best for your application.

Conduit

Liquid Tight Flexible Metal Conduit LFMC (shown) is the most common conduit used in the manufacture of branch circuit power distribution cables, and PDU Cables offers its LFMC in eleven standard colors to help organize and manage dual power feeds. Liquid tight flexible metal conduit jacketing material is a high quality, rugged, flame retardant flexible PVC compound which resists oil, mild acids and exposure to sunlight and offers outstanding protection in wet and oily conditions.For those who prefer Greenfield, PDU Cables will readily substitute either reduced wall aluminum or reduced wall steel flexible metal conduit. While permitted for use in ITE raised floor environments (NEC 645), it is not suitable in damp or wet conditions.