Labeling

Cable Labeling Improves Identification

Cables need to be labeled at each end to ensure that when there is a problem, the cable can be simply identified, and in doing so, reducing the time it takes to track down and resolve an issue. Labeling the cable to include power source and destination for the device and the PDU’s, will ensure you will be able to trace cables to power source and make equipment upgrades or replacements simpler.

Cable Labeling

Labeling cables, be it a power or data cable, can prove to be critical if a problem arises. Labeling of power cables allow for easier installation when on site and for quicker isolation of cables if you need to shut power down. Cable labels should be secured in a way that will make them accessible, yet difficult to remove.

|

|

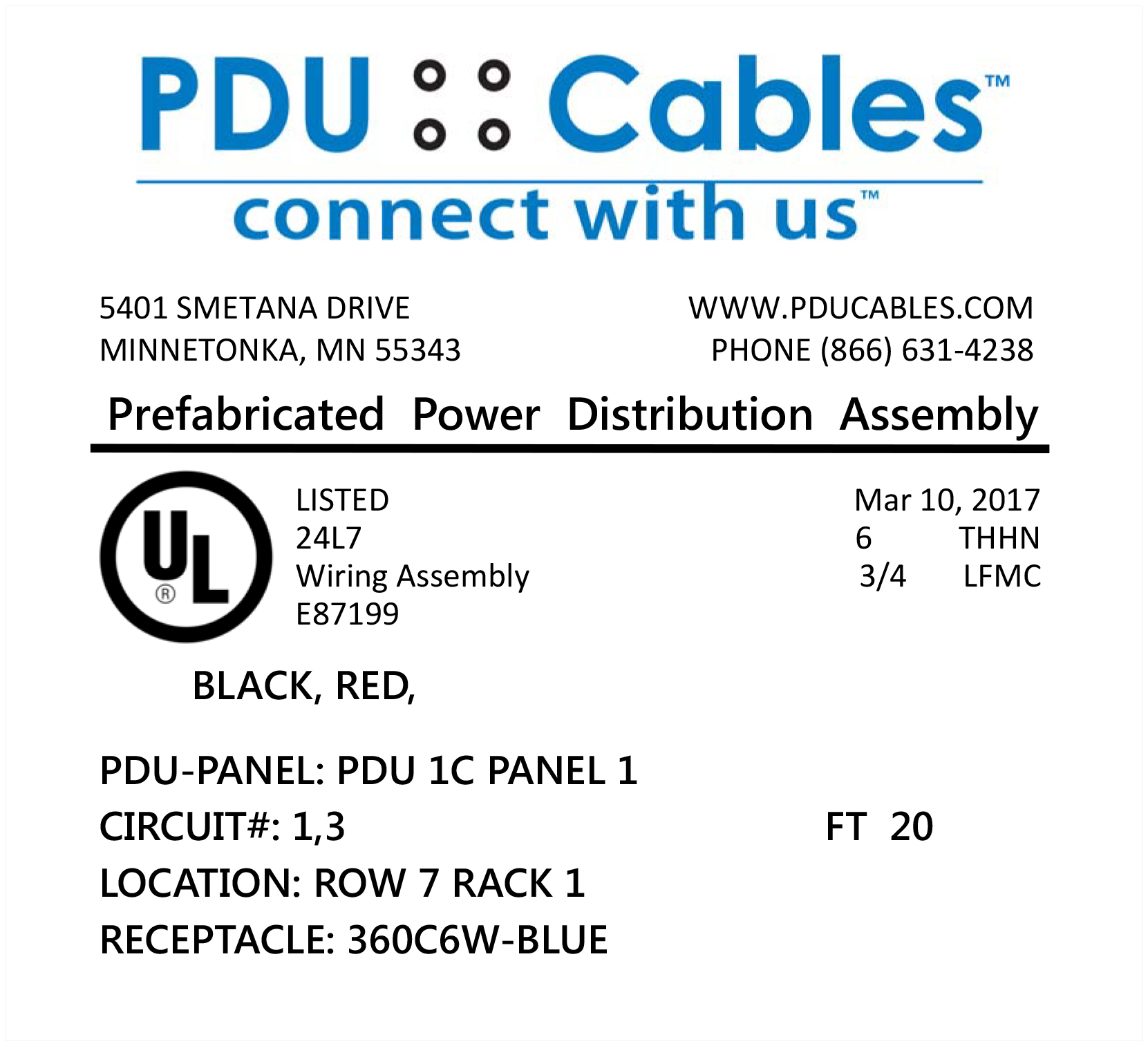

Custom Labels Reference: UL Certification Note: Custom label fields available for additional required label information.

|

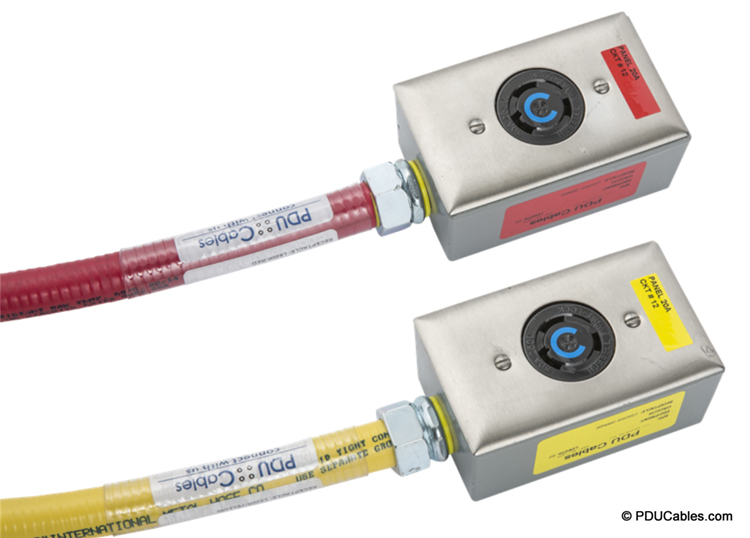

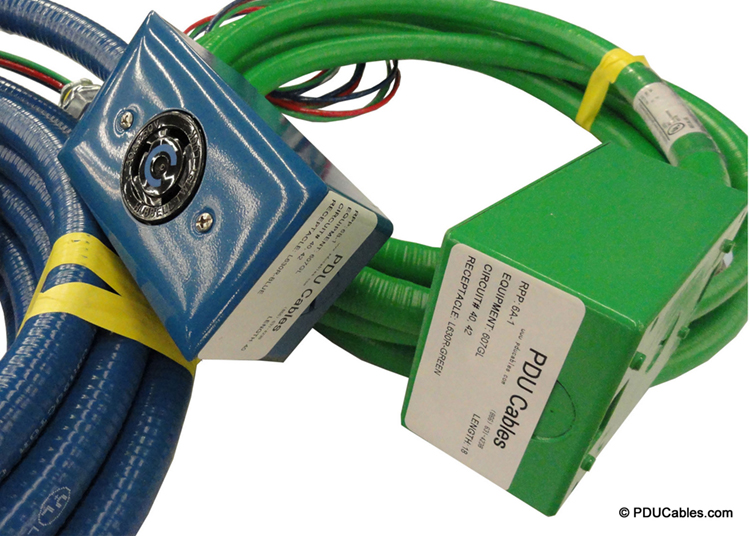

Colored Labels

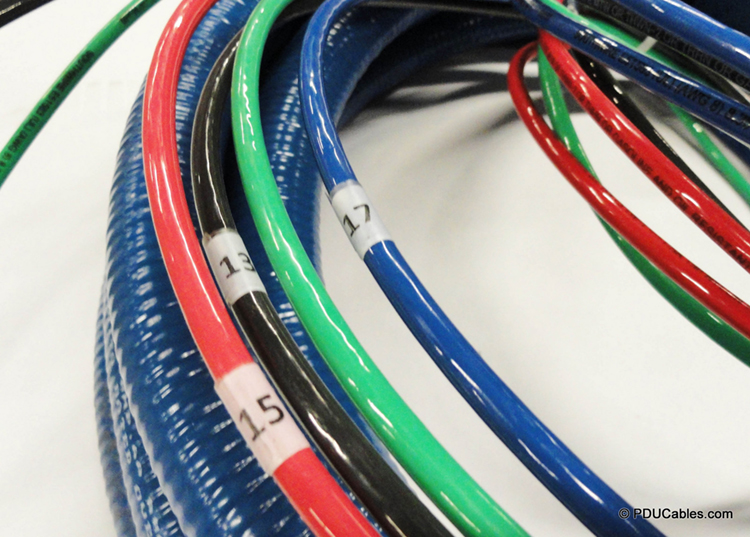

Conductor Labels

Custom Labeling

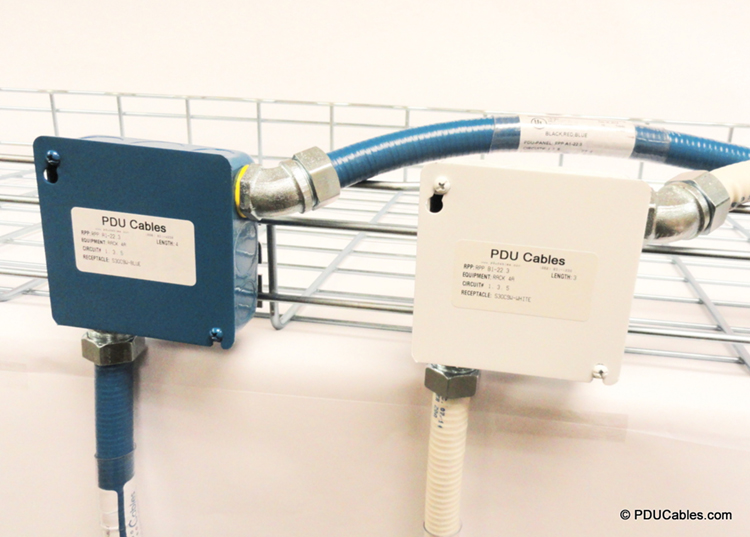

- Box labels

- Faceplate labels

- Additional labels throughout the conduit length

Conduit Labels

Heat Shrink Tubing Secures Each Conduit Label

Colored Box Labels Match Colored Conduit

Colored Faceplate Labels Match Colored Conduit

White Labels on Colored Boxes and Faceplates

Conductor Labeling Speeds Installation

Customized Box Labeling Options

Extra Conduit Labeling

Box Labels Under a Raised Floor

Labeled Junction Box with IEC 309 Pin and Sleeve Drop Cord

Box Labels added to a IEC 309 Connector

Colored Labels are Perfect for Greenfield Conduit